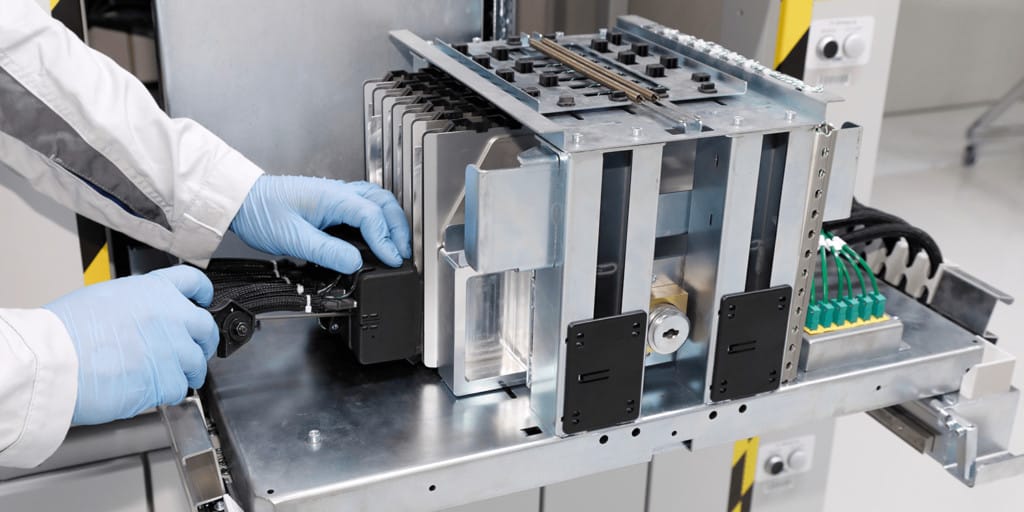

As electric vehicles continue to storm the automotive market, a new challenge has arised. What happens to the end-of-life electric vehicle batteries? Volkswagen (VW) has found a solution.

Many manufacturers are creating sustainable “second-life” solutions to electric vehicle batteries. Nissan, for example, is converting Leaf batteries into stationary energy storage systems. Yet, VW is the first car manufacturer to take aim at batteries that cannot serve a second life. They have opened a battery recycling plant in Salzgitter, Germany, which is breaking down end-of-life batteries from electric vehicles.

Instead of repurposing the batteries like Nissan, VW will have to dismantle the batteries completely, separating, grinding, and drying each individual component. The aim is to extract and treat raw materials within the batteries, to circulate back into production. Each VW battery contains materials such as; lithium, copper, aluminium, manganese, cobalt, and graphite.

The raw materials in used batteries are just as valuable as those in new ones, explains Mark Möller, Head of Volkswagen’s Business Unit Technical Development & E-Mobility. “In the future, we intend to support our battery cell production with the material we recover. Given that the demand for batteries and the corresponding raw materials will increase drastically, we can put every gram of recycled material to good use.”

In its early stages, and the early stages of mass electric vehicle distribution, the Salzgitter plant estimates that the factory won’t run at full capacity until the end of the decade. However, Volkswagen is beginning a pilot study this year with 3,600 battery systems, with the aim of scaling up each year.