What Is A PCB Board?

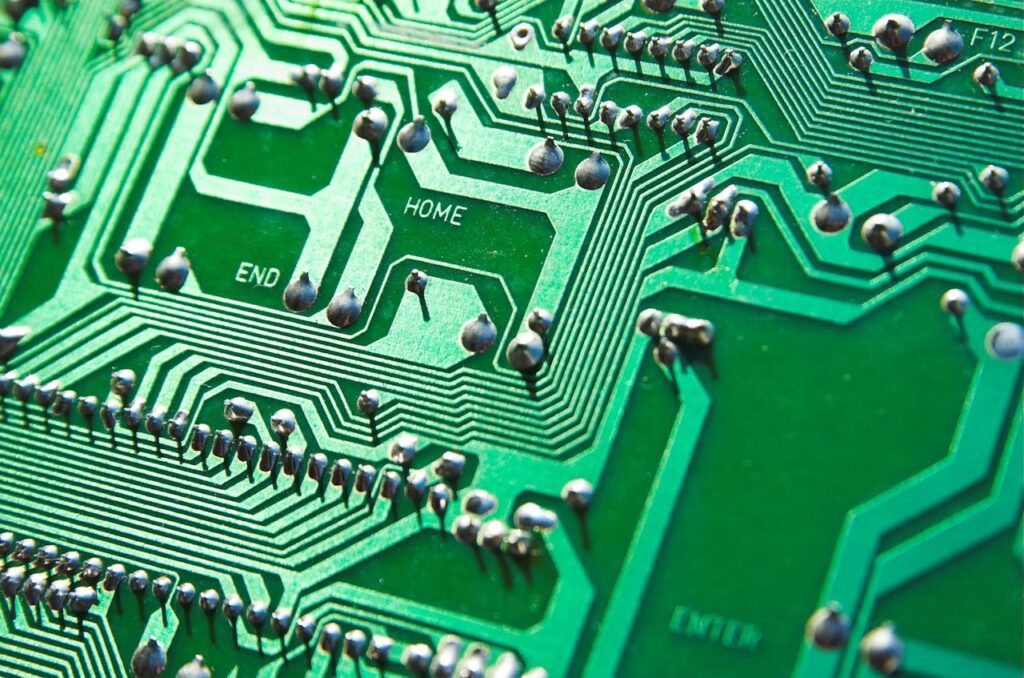

A PCB board, or Printed Circuit Board, is the backbone of most electronic devices. It’s the green (or sometimes blue or red) board you’ll see inside a gadget, filled with intricate copper lines and small components like resistors, transistors, and capacitors.

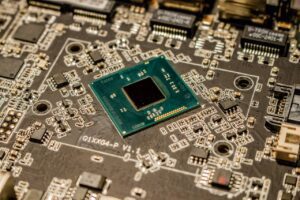

These boards act as the nervous system of electronics, allowing signals and electricity to travel between components seamlessly. Whether you’re using a smartphone, laptop, computer, TV, chances are there’s at least one PCB inside making everything work smoothly.

Despite their small size, PCB boards pack a big punch. They’ve become essential to modern life, powering everything from personal electronics to industrial machinery. Their design and composition have evolved over decades, making them more compact, efficient, and complex.

What Is A PCB Board Used For?

Printed circuit boards are used across almost every industry. In consumer electronics, they’re found in mobile phones, tablets, gaming consoles, and televisions. In automotive systems, they control everything from navigation to engine management.

They’re also vital in medical devices, aerospace technology, telecommunications, and industrial equipment. Anywhere there’s a need for compact, reliable electrical circuits, you’ll find a PCB doing the heavy lifting.

PCBs can be single-sided, double-sided, or even multilayered depending on how complex the electronic task is. With the rise of IoT and smart technologies, the demand for sophisticated PCBs has skyrocketed, reinforcing their importance in today’s digital world.

Simply put, if it has a chip or needs a current to flow in a precise direction, it likely needs a PCB.

What Are Printed Circuit Boards Made Of?

Printed circuit boards are made from a mix of non-conductive substrates and conductive pathways. The base material (or substrate) is typically made from fiberglass (FR4) or composite epoxy, offering a solid yet insulating foundation.

The conductive traces—the lines that carry signals—are usually made from copper. These are printed or etched onto the board in intricate patterns to form circuits. On top of the copper, a protective layer called a solder mask (often green) is applied to prevent short circuits and corrosion.

Some PCBs also include gold plating or silver finishes on connector areas to improve conductivity and durability. Components are soldered onto the board using tin-lead or lead-free solder, depending on environmental and industry standards.

This combination of metals and plastics makes PCBs efficient—but also challenging to dispose of, which brings us to their environmental impact and recycling.

How Do I Dispose Of PCB Boards?

Disposing of PCBs isn’t as straightforward as throwing them in the bin—and it shouldn’t be. PCBs contain valuable metals like gold, copper, and silver, as well as hazardous materials that can harm the environment if not handled properly.

The most responsible way to dispose of them is through a certified electronics recycling service like Collect and Recycle. We specialise in the collection, transportation, and environmentally-safe processing of PCB boards, ensuring that valuable resources are recovered and harmful substances are managed correctly.

When you recycle PCB boards with us, we:

- Safely dismantle electronic devices.

- Sort and segregate PCB materials.

- Extract reusable metals and responsibly dispose of non-recyclables.

- Comply with WEEE and environmental regulations to protect our planet.

Whether you’re a business with surplus electronics or a team upgrading your tech, we offer a convenient and compliant PCB disposal solution. Recycling with us not only helps reduce e-waste but also supports the circular economy by putting materials back into use.